Resharpening & Recoating Services

- By properly resharpening carbide tipped tools, the end user can greatly enhance the value of the tooling investment

- It is important that certain techniques for resharpening be used to maximize the tool's life and productivity

- A resharpening schedule should be implemented based on proven tool life to avoid excessive downtime or catastrophic tool failure

REAMERS

Resharpen the chamfers using the factory primary and secondary relief angles specifications. If necessary, grind the secondary reliefs on the steel body for proper clearance. Do not grind the flute faces.

COUNTERBORES

Resharpen cutting edges to remove wear lands, then reestablish the primary and secondary lands as needed.

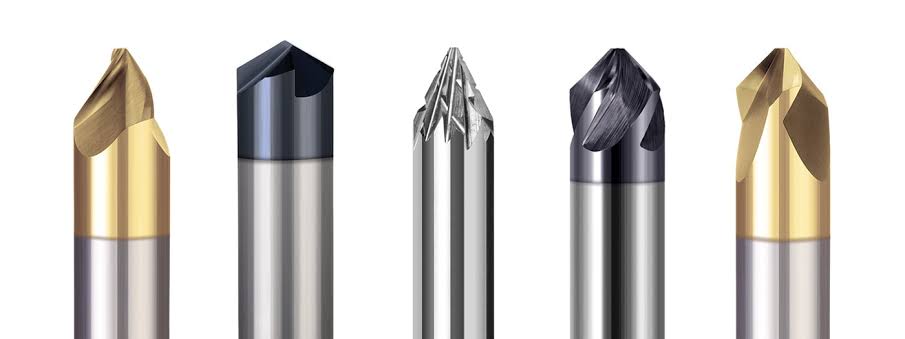

COUNTERSINKS

Face grind to remove wear land(s) or cam relieve to factory specifications.

MILLING CUTTERS

Re-relieve to factory specifications. Regrind side teeth where cutter thickness is not critical.

DRILLS

Resharpen the lips and check lip relief angle, lip heights and chisel edge angle (refer to original factory specifications). If the drill point was originally cam relieved then it should be resharpened as cam relieved. If there are primary and secondary reliefs on the drill, then this should be repeated using standards from the factory for each drill diameter.

END MILLS

For center & end cutting tools: Resharpen the end cutting edges and reestablish the primary lands per original factory specifications.

For slotting and peripheral cutting tools: Relieve diameter to remove wear lands and reestablish factory primary and secondary lands. For radial edged tools, hone a .003" to .005" land on cutting edges. Clearing the steel body may be necessary after several regrinds to prevent dragging.

COATED TOOLS

Resharpening methods for preserving the flute face coating:

- Drills - Grind lips only

- Reamers - Grind relief on chamfers only

- Counterbores - Grind relief on cutting edges only

- End Mills - Grind relief on OD and/or end teeth only

- Milling Cutters - Grind relief on OD and/or side teeth only